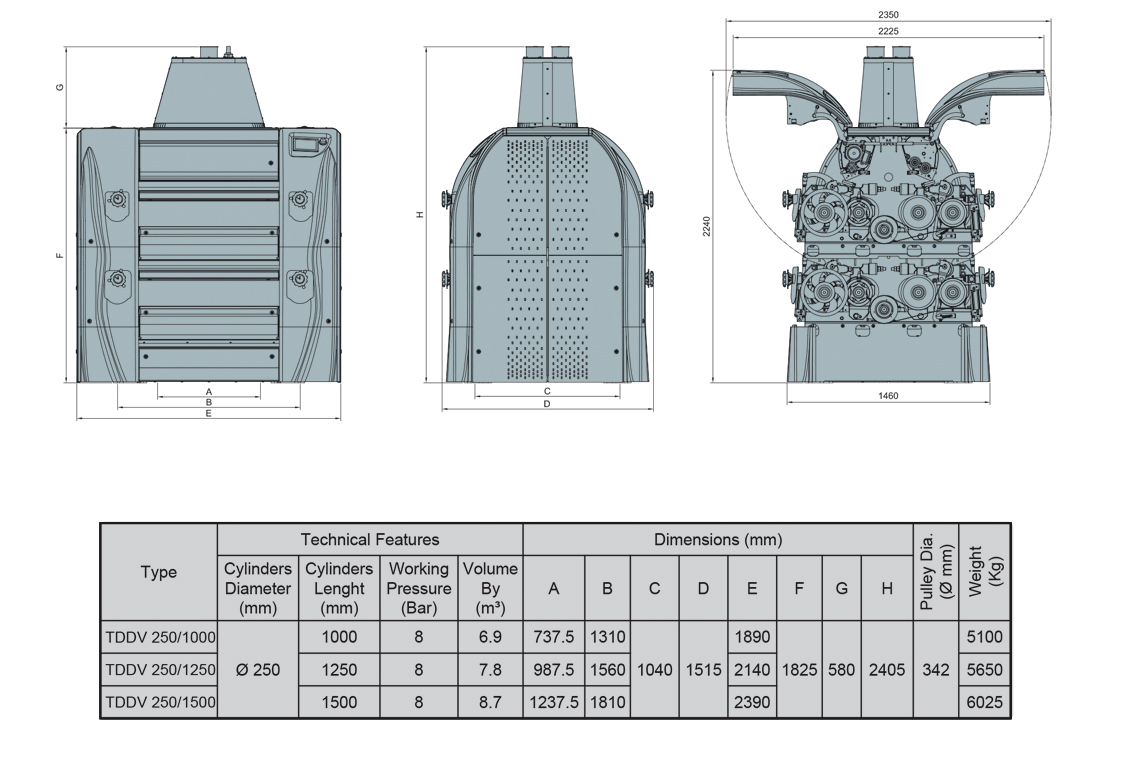

Double Pneumatic Roller Mill

The grain enters the roller mill through product inlet hopper, from which it is conveyed to the feeder rolls and then to the milling rolls. Capacitive level sensors or loadcells adjust amount of the grain which is placed in the product inlet hopper. A pneumatic system is used for the automatic engagement/disengagement of the milling rolls and for adjusting milling distance, using a graduated hand-operated Wheel.

These fine-tuning Wheel can be reproduced using an electric system with a stepper motor or servo motor. With the specialized air channel system, provides uniform flow of grain between the rolls.

FEATURES

• New Aesthetics And Ergonomic Design

• Minimum Noise Level

• Minimum Parts Replacement Time

• Easy Maintenance And Cleaning

• High Stability

• Low Operation Cost

• Long Term Of Using

• Maximum Ease Of Use

• Maximum Sanitation